Horizontal Band Saw Worm Gear Replacement for 4x6, 4 1/2x6, 5x6

- Jan 8

- 4 min read

Updated: Jan 12

Our 5x6 mitering horizontal band saw stopped working due to a worn worm gear. The worm gear is made from softer materials (bronze or brass) than the worm (steel), therefore the worm gear will wear out first and is sacrificial.

The specific model of band saw I have is a BS-128HDR METAL BAND SAW purchased in ~2012 from Northern Tool. It's a 5x6 cut size band saw, but seems to use the same gears as the less expensive, common 4x6 and 4.5x6 band saws like those sold at Harbor Freight, Grizzly, etc.

The BS-128HDR is still sold by a few different brands.

Here's the Grizzly parts list related to the gearbox:

This is what the gearbox on ours looked like with the cover removed.

Should have changed the gear oil occasionally.

The worm gear shaft measures 15mm.

The total gear width including hub is 25.86mm

The worm gear teeth width is 15.29mm

The worm gear hub diameter is 27.27mm

The worm gear key width is 5mm (4.95mm).

GEAR REPLACEMENT SOURCES

ACCURA MACHINE TOOLS

4 1/2 x 6 metal band saw bronze drive gear and shaft only 20 tooth

$55

Description: 20 tooth gear fits many of the made in Taiwan band saws. Specs are as follows: 1.837 app overall major diameter, gear face app .5945 wide, overall width with hub is app 1" on the gear portion, app 4" long shaft w/ 1" long 5 mm keyway.

Gear only, shaft sold separately.

GRIZZLY offers parts and sells the worm gear, but it is pricey.

WORM GEAR Part #: (Part 91 in diagram) P9742091

EBAY (seller name Makocomposites)

$95

Description: 21 tooth bronze transmission gear. 15mm shaft hole, 5 mm keyway. Will fit most 4 1/2 x 6 metal cutting bandsaws. More commonly called 4x6 metal cutting bandsaws. Should also replace 22 and 23 teeth gears as they increased the number of teeth on the gear.

WORM GEAR LUBRICANT

Worm gears need special lubricants. These oils must be relatively high in viscosity—especially as loads or temperatures increase—and must also provide enhanced lubricity to cope with continuous sliding contact.

Viscosity plays a critical role in keeping the worm from contacting the wheel. While the exact viscosity depends on gear size and loading, oils in the ISO 460 to ISO 680 range are commonly used, and ISO 1000 is not unusual.

A common choice for worm gears is mineral-based compounded gear oil. While no additive can completely eliminate sliding wear, the fatty compounds in these oils improve lubricity and provide additional protection against metal-to-metal contact.

Another option is mineral-based extreme pressure (EP) gear oil. These can perform well, but caution is needed when the worm wheel contains yellow metals such as bronze or brass. If operating temperatures are low or yellow metals are absent, EP oils can be effective.

Polyalphaolefin (PAO) gear oils are also well suited for worm gears due to their naturally high lubricity. When using PAO oils, the additive package should be carefully reviewed. Anti-wear (AW) formulations are usually acceptable, but compatibility with yellow metals must be verified.

Wear metal levels should be closely monitored through oil analysis, as some AW additives can react with brass, though typically far less aggressively than EP additives. PAO oils are also available for applications that require performance over a wide temperature range.

A fourth option is polyalkylene glycol (PAG) lubricants, which are becoming increasingly popular. PAG oils offer excellent lubricity and perform well at low temperatures since they lack the waxes found in many mineral oils. However, they are not compatible with mineral oils and may attack certain seals and paints, so care must be taken before switching to this type.

LUBRIPLATE Synthetic Worm Gear Lubricant

ISO Grade 460, Polyalphaolefin (PAO)-Based Synthetic oil

600W STEAM CYLINDER OIL

600W Steam cylinder oil is recommended for bronze worm gear applications, and has been in use for a long time. It is however difficult to find in small quantities.

REPLACING THE GEAR

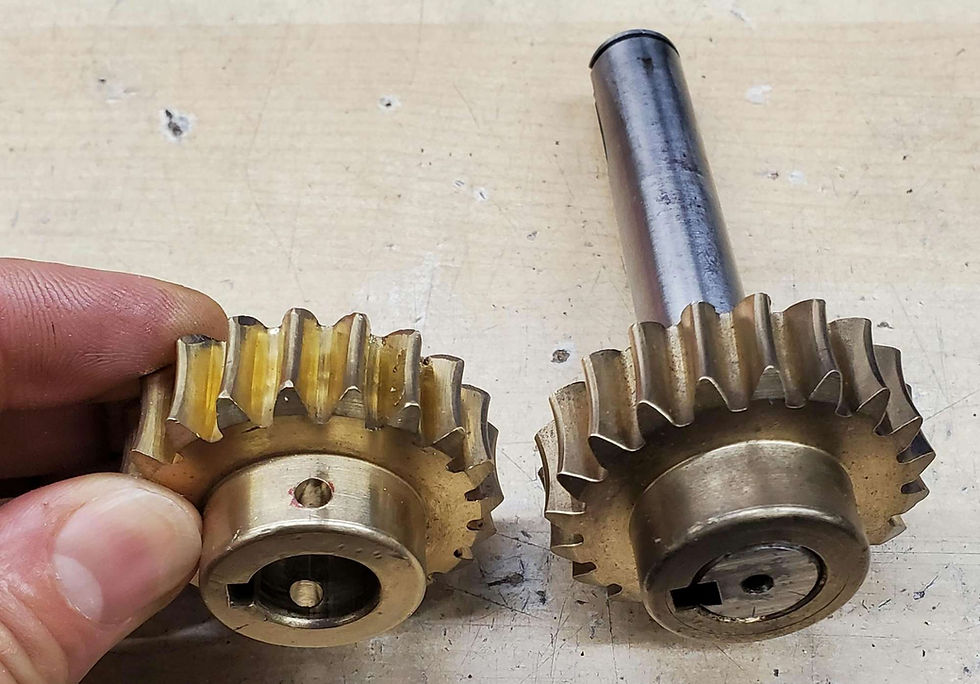

These gears were ordered from ACCURA Machine tools. They were shipped by Hamilton Tool and Supply and arrived in 2 days.

I was surprised the shafts were included, because the listing said it was for gear only and shaft was sold separately.

Unfortunately the shaft is a little short for our band saw, so we had to remove the gear and use the original shaft.

(Original shaft is on the left.)

The retaining pin has to be pressed out of the gear.

With the retaining pin out, a gear puller is used to remove the gear from the shaft.

Gear removed from the shaft.

The gear was pressed on the old shaft, pin was pushed into the gear.

The gear is put back into the gear box.

Slide the gear/shaft all the way in until it bottoms out.

On the other side (the blade pulley side) where the shaft comes out, add the spacer.

Put the key in the keyway.

Slide on the blade pulley.

Put the retaining clip back in the slot at the end of the shaft. Our retaining clip is in bad shape and needs to be replaced.

The clean gearbox without any oil.

Fill the gearbox with oil that is suitable for a worm grear box with a bronze worm gear. We use LUBRIPLATE Synthetic Worm Gear Oil.

Gearbox is filled like it was before. I feel like it needs to be tilted and filled more.

It may be necessary to add some RTV gasket sealant around the edges of the gearbox to create a better seal between the cover.

Put the cover plate back on. The hydraulic feed arm bracket is also attached to the gearbox using the same screws.

The band saw is working like new again. It's unfortunate that it is relatively difficult to find a replacement worm gear, and that the manufacturers are charging $100 for one, which is 1/6th the price paid for this saw.

Comments